Delta CP2000 VFD - 10 HP, 460V, 3-Phase Input/Output | Model VFD075CP4EB-21

Delta CP2000 VFD - 10 HP, 460V, 3-Phase Input/Output | Model VFD075CP4EB-21

Couldn't load pickup availability

The Delta CP2000 VFD (Model VFD075CP4EB-21) is a reliable 10 HP, 460V Variable Frequency Drive tailored for industrial and commercial variable torque applications. Rated for 18A at 460V, this VFD is ideal for fans, pumps, and HVAC systems requiring precise motor control. Built with Delta’s renowned energy-efficient technology, it features a compact IP20-rated enclosure, making it perfect for secure indoor installations. The CP2000 series delivers optimized performance and seamless integration for modern industrial systems."

-

Features and Benefits:

- Horsepower: 10 HP with 120% overload capacity for versatile applications.

- Voltage Compatibility: 460V input/output for industrial motor systems.

- Variable Torque: Maximized for applications with fluctuating load conditions.

- Three-Phase Input/Output: Stable and efficient power delivery for consistent performance.

- Compact Design: IP20-rated enclosure ensures safe and secure installations.

Product Specifications

Product Specifications

The Delta CP2000 VFD (VFD075CP4EB-21) is a high-performance 10 HP, 460V AC drive engineered for energy-efficient motor control and dependable performance in demanding environments.

Applications and Uses

Applications and Uses

Optimized for variable torque applications such as fans, pumps, and HVAC systems, this VFD ensures reliable motor control with energy efficiency in industrial and commercial settings.

Key Features and Benefits

Key Features and Benefits

10 HP Capacity: Designed for light-to-medium-duty operations with 120% overload capacity.

Variable Torque: Delivers energy-efficient performance for applications with dynamic load demands.

Three-Phase Input/Output: Ensures stable motor control and efficient power distribution.

Compact and Durable Design: IP20-rated enclosure for secure indoor use.

Energy Efficiency: Reduces operational costs while maintaining reliable motor performance.

Installation and Maintenance Guidelines

Installation and Maintenance Guidelines

Install the CP2000 VFD in a ventilated indoor location compliant with IP20 standards. Follow proper grounding and wiring practices as outlined in the user manual. Routine maintenance includes inspecting connections and clearing dust every 6 months, with an annual diagnostic check for optimal operation.

Warranty and Support

Warranty and Support

The Delta CP2000 VFD includes full support for installation, troubleshooting, and maintenance. Delta’s commitment to quality ensures dependable operation with robust warranty coverage.

In-Depth Product Information and Specifications for Delta CP2000 VFD - 10 HP, 460V, 3-Phase Input/Output | Model VFD075CP4EB-21

Efficiency Comparison Chart

Applications and Recommended Use Cases

Energy Cost Savings Over Time

Technical Specifications Breakdown

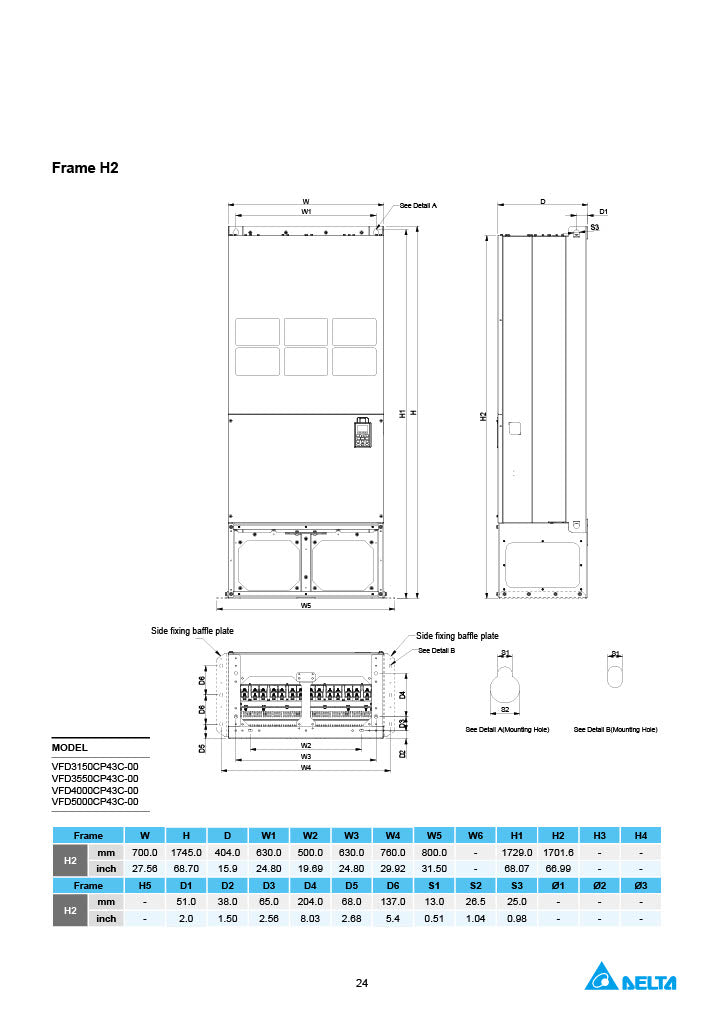

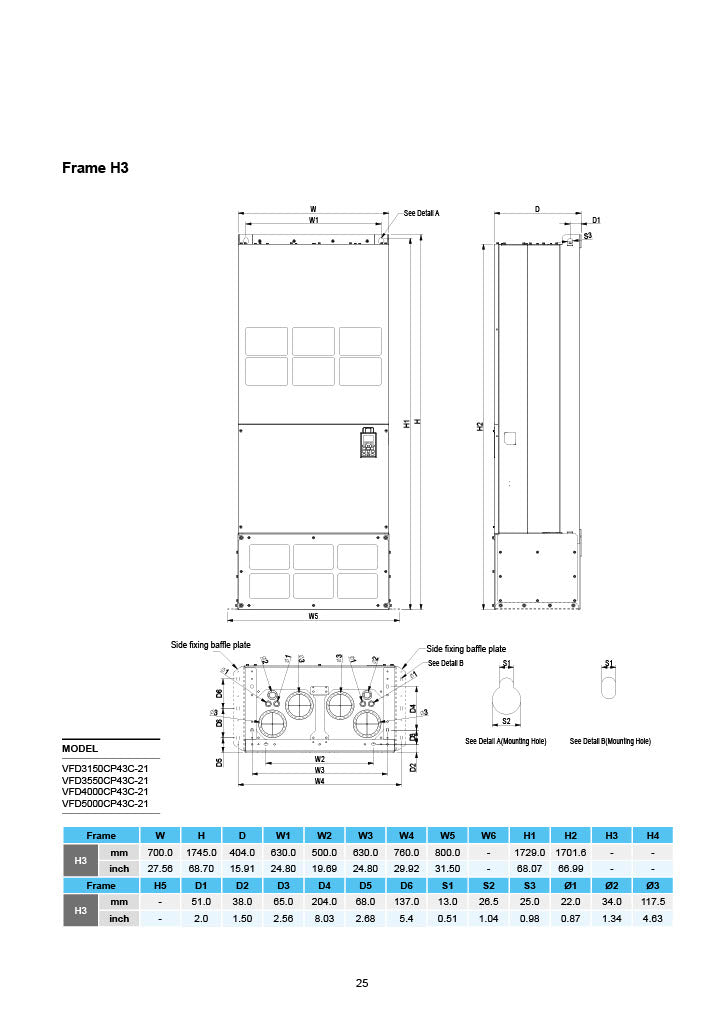

| Specification | Value |

|---|---|

| Horsepower (HP) | 10 HP |

| Input Voltage | 460V |

| Output Voltage | 460V |

| Rated Amps | 18 A |

| Output Amperage | 18 A |

| Phase Input/Output | 3 Phase |

| Torque Type | Variable Torque |

| Enclosure Rating | IP 20 |

| Series | CP2000 |

| Frame Size | A |

| Weight | 6.39 lbs |

Maintenance Schedule and Requirements

Check all electrical connections for tightness and inspect for wear to ensure safe, continuous operation.

Remove dust buildup from vents and surfaces to maintain optimal airflow and cooling efficiency.

Conduct a full diagnostic test to ensure optimal performance. Check for unusual sounds or vibrations indicating potential issues.

Resources

View all-

Understanding Motor Requirements in Food & Beve...

Struggling with motor selection for your food processing facility? This comprehensive guide breaks down everything from washdown requirements to regulatory compliance. Learn which motors you need, why you need them,...

Understanding Motor Requirements in Food & Beve...

Struggling with motor selection for your food processing facility? This comprehensive guide breaks down everything from washdown requirements to regulatory compliance. Learn which motors you need, why you need them,...

-

Electric Motor Safety: Essential Protocols for ...

A practical guide covering safety measures when working with and maintaining electric motors, which complements many existing posts regarding motor efficiency and maintenance.

Electric Motor Safety: Essential Protocols for ...

A practical guide covering safety measures when working with and maintaining electric motors, which complements many existing posts regarding motor efficiency and maintenance.

-

Understanding ODP Motor Enclosures and Applicat...

Electric motors power a wide range of industrial and commercial equipment, making motor reliability essential for productivity. However, a motor’s performance isn’t solely determined by its internal components—its enclosure plays...

Understanding ODP Motor Enclosures and Applicat...

Electric motors power a wide range of industrial and commercial equipment, making motor reliability essential for productivity. However, a motor’s performance isn’t solely determined by its internal components—its enclosure plays...